Plastic bag ban fuels packaging wars

A SHOPPER in Legazpi City holds a brown paper bag containing dry goods. Albay province has banned the use of plastic bags on dry goods and of styrophor starting May 31. Photo by Jojo Los Baños/Inquirer Southern Luzon

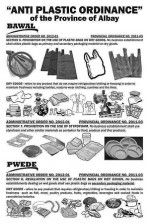

Editor’s Note: Albay province and Davao City are the latest local government units that have banned the use of plastic bags as packaging materials for dry goods. (See poster.) As the list of LGUs curbing the use of plastic bags grows, the Philippine Plastic Industry Association (PPIA) has extolled the benefits of plastic bags, saying these are reusable and utilize less energy and water to produce than paper bags. (See Talk of the Town, April 1.)

Article continues after this advertisement

In the interest of fair play, we are running the side of the Technical Association of the Pulp and Paper Industry of the Philippines, which reacted to the points raised by the PPIA against paper bags, and of a group that promotes the use of biodegradable plastic bags.

Paper practical substitute

By Ray Geganto

Article continues after this advertisementHaving worked as a pulp and paper engineer for many years and having used plastic and paper bags as an average citizen, I find some assertions of the Philippine Plastic Industry Association (PPIA) inaccurate or misleading and wish to make a correction.

In the Philippines, all paper products, including paper bags and cartons are derived from recycled fiber. The process is repeated several times.

In countries where paper is made directly from trees (virgin pulp), the trees claimed to have been cut (the correct figure is 12 to 14) did not come from virgin or natural forests but were harvested from tree plantations or robust forests sustainably managed under responsible stewardship or through state-regulated timberlands.

Tree planting

For each tree cut, more are planted or allowed to regenerate, resulting in growth and expansion of forest lands rather than denudation as seen in Scandinavia, North America, New Zealand, South America and now Indonesia, Thailand and China.

These are countries where the largest pulp and paper industries are located. Manufacturing paper and other forest-based products provides the economic incentive to plant trees, thus restoring and sustaining forests in a productive way.

Plastic bags, if recovered, are not recycled back into its original form but into lower-grade applications of plastic. The original plastic bag material, polyethylene, comes from petroleum and is imported into the Philippines as virgin resin in the form of pellets.

Renewable fibers

Petroleum and its derivative for plastic, polyethylene, are not renewable and the country imports huge amounts. Paper, on the other hand, comes fully as a recycled material or partly from renewable fibers like replanted trees and agriculture wastes.

The 1 gallon of water needed to produce a paper bag (of 55.2 grams), equivalent to 68 cubic meters per ton of paper, cited by PPIA president Crispin Lao, is high by paper industry standards.

Recycled paper mills use only 4 to 10 cubic meters of water per ton of packaging paper. Water-use comparison with plastic should be on the full raw material-final product conversion, not just on the conversion process (as from the forming of plastic bags from polyethylene pellets by injection molding or sheeting process).

Footprints

Recycling paper mills use agriwastes like coco shell, rice hull and plantation wood or 450 kg of coal per ton of paper to generate steam used in drying paper, while forest-based paper mills are self-sustaining in fuel (using waste heat from wood wastes and pulping liquor burned in recovery boilers).

Electricity consumption in most local paper mills is about 350 to 450 kilowatt hour (kWh) per ton. Again, critics should compare these figures correspondingly with those in making plastic all the way from petroleum.

Paper not recovered is compostable into fertilizer and does not clog our sewers and waterways. Birds and marine animals that eat paper in our surroundings by mistake do not choke on or die from it. In rivers and seas, paper degrades and does not cover corals or stop photosynthesis and interfere with natural processes.

Jobs, investments

Like the plastics industry, the local paper industry directly and indirectly provides livelihood to more than one million workers and wastepaper sorters and gatherers. The local paper industry has invested billions of pesos in paper mill and related equipment.

Using locally manufactured paper helps our countrymen keep their jobs and support local industry, instead of shifting employment to certain countries from where we import petroleum or its derivatives for plastic.

By any means, it is not true that paper is considered inferior to plastic from the standpoint of environmental and social aspects, as what Lao’s article may have impressed upon readers.

The paper industry can fully meet the quality requirements of the paper-packaging market by using available technologies. Paper from recycled paper wastes can be made stronger with the use of modern equipment, strength-enhancing agents and strong fibers like high-grade paper wastes, virgin pulp (if required in specific applications), or even long fibers like our abaca.

What is needed is for the packaging and paper industries, together with the consumer sector and the Bureau of Product Standards, to define and establish the quality standards for packaging paper, so the paper industry can implement additional measures to fully achieve paper-packaging quality requirements.

The application of paper to replace plastic in packaging has progressed well in so many countries which have promoted the regulation of plastic mainly for environmental reasons.

Because it is available locally and is cheaper than cloth bags, paper is a practical substitute for plastic bags in consumer goods packaging.

(Ray Geganto is the chair of the technical committee of the Technical Association of the Pulp and Paper Industry of the Philippines. He can be reached at rng1quest@hotmail.com.)